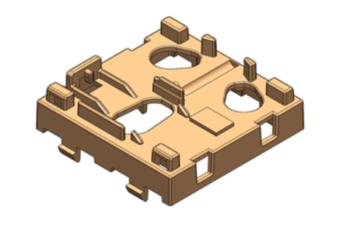

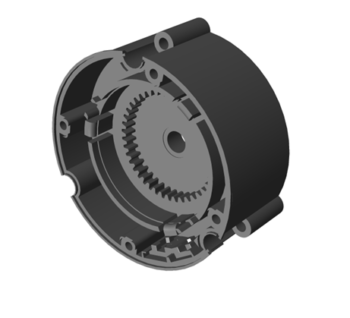

PLASTIC DESIGN PRODUCT

Hand held Printer design

Our Engineering team has very good understanding of Plastic Product Design for Injection Molding. Our team has Designed Injection Molds for various parts like Automotive Interior components, wireless modem, Connectors etc and graduated to Design of Plastic parts and Products for Molding.

Injection Molded Plastics component Design often require a deeper knowledge of the plastics manufacturing terminologies such as Parting line, Side cores, Drafts etc needed for Moldability. Tooling for plastics is often expensive and plastic parts are not as durable as metal.

Inputs

- Industrial Design in the form of 3D model

- Design Guidelines specifying functional and aesthetic requirements

Project Execution Responsibilities

- Explore cost saving options in terms of ease of Mold design, cost of assembly, Handling etc.

- Follow Industrial Design given by client and package all internal components as per client guidelines

- Develop moldable plastic part/assembly design, meeting the entire functional requirement given by the client.

- Model conversion according to tooling requirements such as drafts, retaining MMC for critical dimensions, rounds addition etc.

- Parting Line based on – component profile / ease of splitting.

- Draft / Undercut analysis.

- Implement Top Down design approach,Prototyping and improvements after study

- Coordinate work among Mechanical, Hardware, software team and client engineers.