Our Team has system-level and module-level design expertise, having working on Design of Process chambers, High-purity gas delivery systems, Power distribution units, Beam Expander modules, Beam bender modules, Equipment enclosures, Support structures, Installation/transport tooling, and more. We have an excellent understanding of semiconductor fab and clean room requirements.

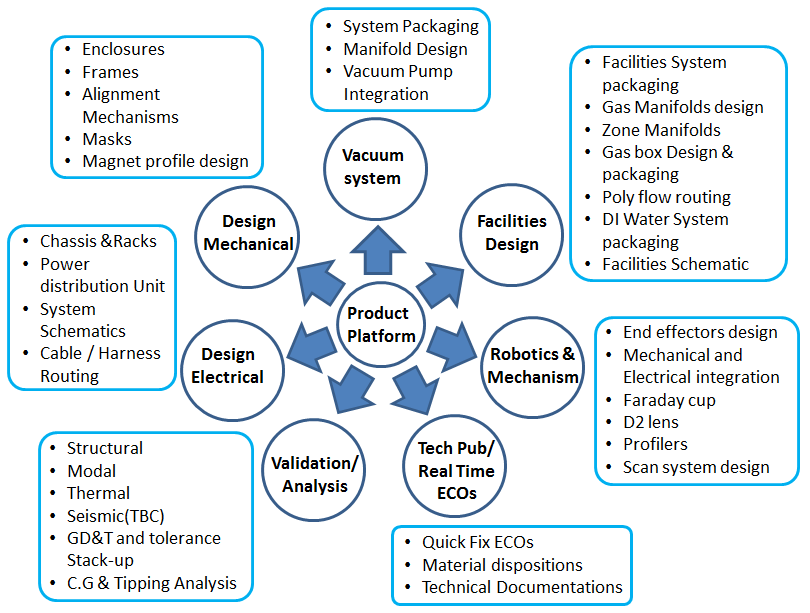

We offer support in the below areas:

Capabilities

- Good understanding of Clean room requirements

- Compatible Materials

- Finish Specifications

- Understanding of P&ID in context of Fab and Sub-Fab sub-system

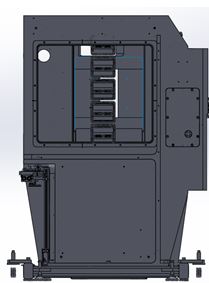

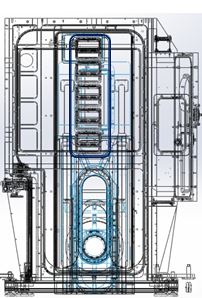

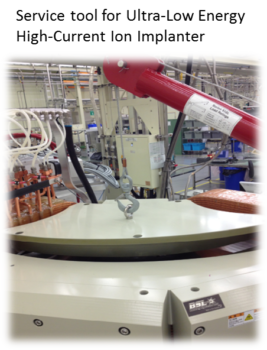

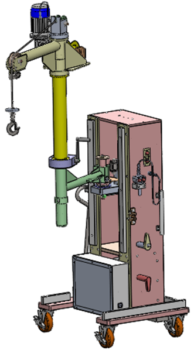

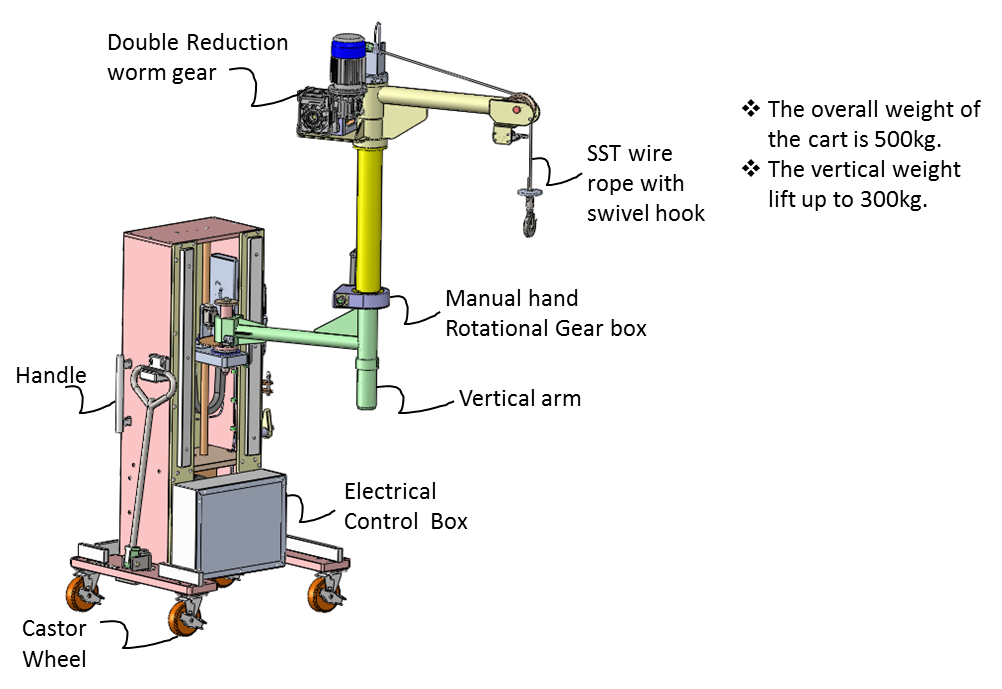

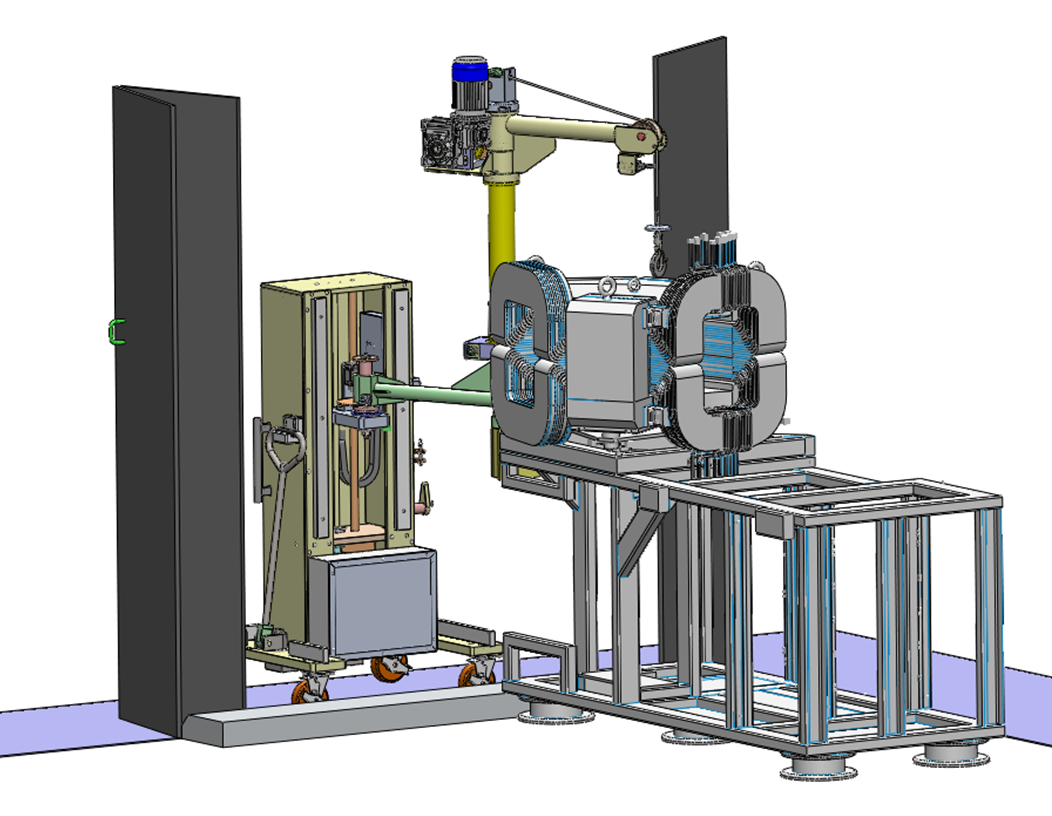

Semiconductor clean room compatible lifting cart

Engineers with variety of exposure in Domains like Semiconductor, Automotive, Material Handling, Office Automation etc

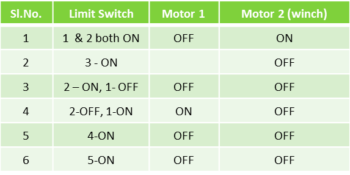

5 limit switches working as interlock

Salient features

Cleanroom compatible design

Built in safety interlocks

Ensures docking

Maximum lift position

Customized design to fit around service area available

Weight limited to be used on raised floor tiles

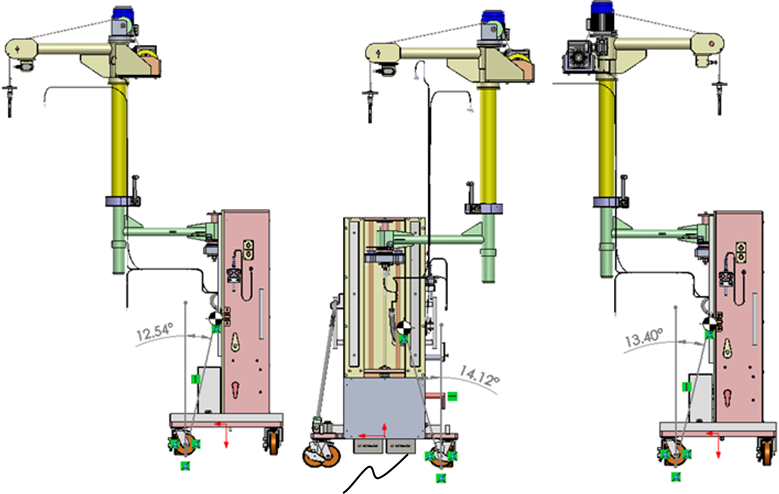

CG analysis

CG position verified, counterweight optimized to ensure the cart doesn’t roll over during tip/tilt

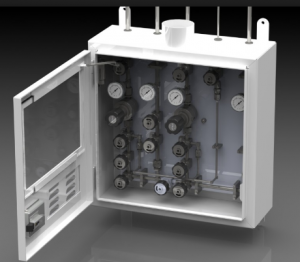

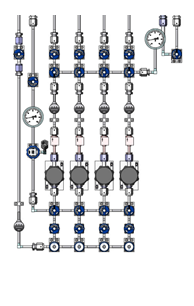

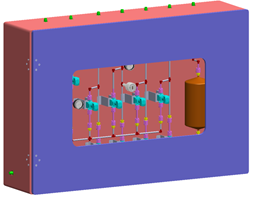

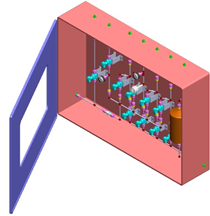

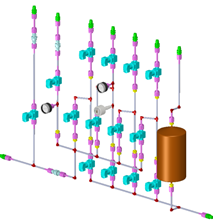

Gas Box

Gas System Plumbing

- Able to create Gas Box Schematic based on Hand sketch of requirements

- Able to choose Gas Box components based on schematic and specifications

- Good understanding of various component notation to be followed for the schematic (eg. Valves, Regulator, MFC, Transducer etc)

- Type of fittings (Male/Female VCR) and critical flow requirements captured on schematic

Team has familiarity with tubing and fittings used for gas flow lines from various vendor

- Swagelok Face seal fitting (VCR)

- Parker VacuSeal Fittings

- Cajon Face seal fitting (VCR)

- Formed Stainless steel Bellows

- Edge Welded Bellows

- PFA tubing

- Pisco Fittings

Braided HosePrimary components utilized to control delivery of process gases into the processing chamber.

- Mass flow controller (MFC)

- Mass flow meter (MFM)

- Pressure transducer

- Purifier

- Regulator

ValveTeam has experience in choosing and interacting with various vendors as listed below

- MKS Instruments

- Brooks Instruments

- Horiba

- Setra

- APTech

- Parker

- Swaglok

Understanding and developing Gas delivery requirements and concepts

- Digest process needs and work on developing schematic using CAD software.

- Set ground rules based on chemicals used and safety standards.

- Develop gas sticks and panel concepts based on requirements.

Gas Box Experience

- Our Engineers have supported various Semi Conductor companies in design of Custom-Engineered Gas Box \ Gas sticks to meet Distinct Process Demands

- Designed Gas Box for the most precise high purity applications to work in the most advanced and stringent production environments.

- Engineered Custom solutions for application-specific needs

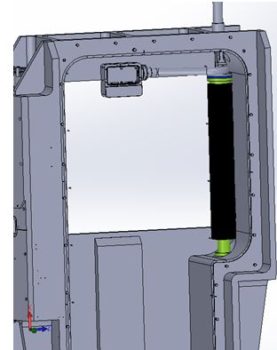

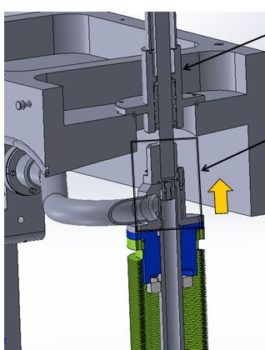

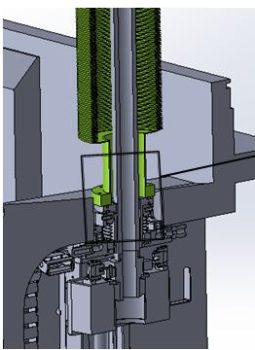

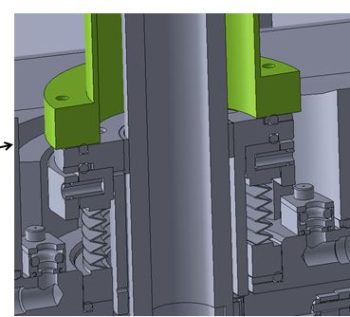

Profiler Drive System and Development

Concept 1

Adding Bellow

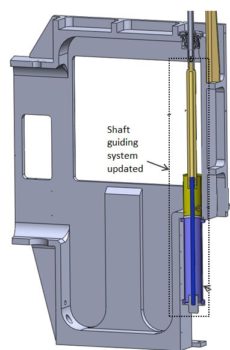

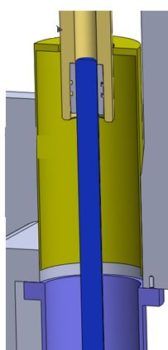

Concept 2

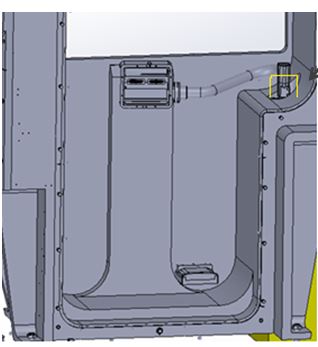

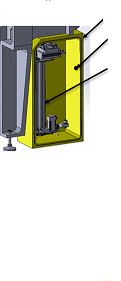

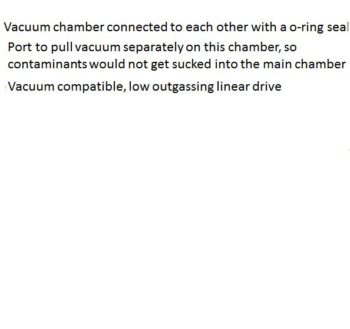

Linear Drive and Rotation Mechanism Enclosed in Vaccum

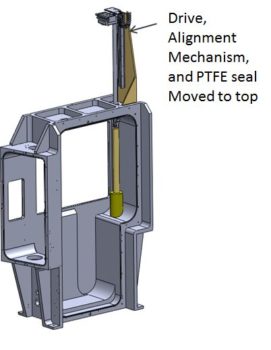

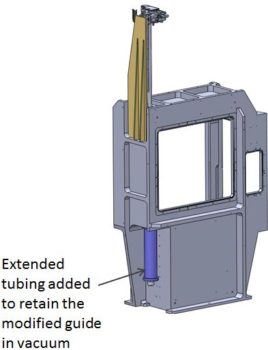

Concept 3

Inverting Seal and Moving the Linear Guide to Top Side

Concept 4

Multi Profiler Head