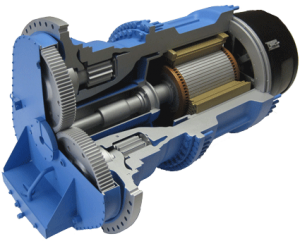

Prototyping and testing allows the designer and client to assess the viability of a design.oped in-house or provided by the customer.Our unique development process allows our clients to start with only a hand sketch, and then we focus our energy

converting it to final manufacturable prototypes i.e.Our team can take inputs in the form of a concept sketch or a 3-D model and proceed to build a prototype for evaluation. Evaluating a prototype allows the production costs to be assessed and finalised. Every stage of manufacturing can be scrutinised for potential costs, then alterations to the design or manufacturing processes, may have to be recommended. This process allows our engineers to check for improvement opportunities and will catch any complications that may arise when developing hard tools.

converting it to final manufacturable prototypes i.e.Our team can take inputs in the form of a concept sketch or a 3-D model and proceed to build a prototype for evaluation. Evaluating a prototype allows the production costs to be assessed and finalised. Every stage of manufacturing can be scrutinised for potential costs, then alterations to the design or manufacturing processes, may have to be recommended. This process allows our engineers to check for improvement opportunities and will catch any complications that may arise when developing hard tools.

Prototyping method is carefully chosen based on the testing to be carried out. Our manufactured prototypes are almost perfect replicas of the final product that will be sold to the market. Our firm understands the importance of having a final fully functional prototype as it often paves the road when clients are presenting to potential investors or potential

Prototyping method is carefully chosen based on the testing to be carried out. Our manufactured prototypes are almost perfect replicas of the final product that will be sold to the market. Our firm understands the importance of having a final fully functional prototype as it often paves the road when clients are presenting to potential investors or potential

buyers. Prototypes can be tested for Form, Fit & Function

Our approaches for Prototyping + Testing:

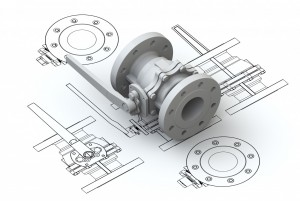

- Customer input (Hand sketch or 2D Drawing etc.,) → 3D Model → RPT/ Machining / 3D Printing → Testing

- Customer input (3D Model) → RPT / Machining/3D Printing → Testing

- Customer input (Idea) → Concept generation → 3D Model → RPT / Machining/ 3D Printing → Testin

Prototype services offered:

Virtual Prototyping – Computer generated renderings

- 3D Printing – Converting 3D CAD files to samples in a matter of hours.

- Conceptual Prototyping – Sometimes known as mock-up prototype are made using state of the art Rapid Prototyping and 3D printing equipment that truly brings your product to life.

- Plastic Molding – It is the commonly used in our prototype process in order to simulate virtually any plastic material in a prototype mold.

- Sheet metal Prototyping – We will deliver your custom one-piece or multi-piece metal enclosures to fit your 3D CAD data and specs submitted.

Testing:

- We will do Form, Fit & Function tests as per the customer test procedure.Outcome:

- Improve or Re-design parts to eliminate identified failure modes, Recommendation to improve function, reduce cost, improve ease of use etc.