Tolerance Stack up analysis, Reverse Engineering, Value Engineering, Cable Routing, P&Id Creation, Pipe routing, Legacy Conversion, Drawing Reviews/Update, Concept Generation, DFX Reviews etc. are the specialized Services we offer. Joscotec is happy to customize any service to your requirements.

Tolerance Stack up analysis, Reverse Engineering, Value Engineering, Cable Routing, P&Id Creation, Pipe routing, Legacy Conversion, Drawing Reviews/Update, Concept Generation, DFX Reviews etc. are the specialized Services we offer. Joscotec is happy to customize any service to your requirements.

Specialized Services

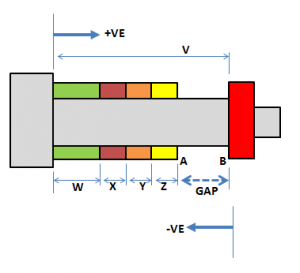

Tolerance Stack up Analysis : Team has good experience in the area of Tolerance Stack-Up analysis using RSS method or Worst case analysis. We make recommendation on the Part or Assembly feature tolerancing, Identify Key characteristic dimensions etc.

Reverse Engineering

This is also referred to as the Part-to-CAD process. It can be said that reverse engineering begins with the product and works through the design process in the opposite direction to arrive at a product definition statement (PDS)

- Based on the client requirement we could either take a physical model and convert into a CAD model physical dimensions, feat res, a

- Take a Product/System – Study the component function and interrelationship and go on to develop a system incorporating all the improvement possible. We provide customers with an alternative Design for sourcing parts for their equipment to upgrade components, improve function etc.

Why use technical documentation from JOSCOTEC?

- We provide you with a complete integrated service, enabling you to:

- Benefit from a complete technical document solution, including technical writing, translation, illustration and finishing services, all tailored to meet your needs

- Avoid time-consuming and complex document production so you can focus on your core business

- Comply with national and international standards as well as local or company-related specifications

- We can address your documentation needs either through turn-key, project basis or through staff augmentation working along with your internal resources.

Our services for technical documentation include:

- High-quality technical illustrations and professional presentations

- Technical writing and editing from a wide range of source materials, including design specifications, engineering documents, schematics, mechanical drawings, and existing versions of documentation

- Production of all types of technical documentation, such as software, operator, maintenance and repair manuals and spare parts catalogues

- Integrating documentation in software or publishing on the Internet

- Editing of product training information

- Preparation of course material and on site training

- Computer Based Training applications (CBT), including e-learning and technical interpretation during training sessions.

ENGINEERING CHANGE ORDER (ECO)

We in JOSCOTEC identifies an issues of the client that may need to be addressed with a change to the product. It ends when the agreed-upon change is implemented. ECOs are used in between to summarize the modifications, finalize the details and obtain all necessary approvals regarding product change.The step carried out by us in the engineering change process are:

- Issue identification & scoping: Someone identifies a problem or issue and determines that it may require a change. The scope of the issue and its possible impact are estimated.

- ECR creation: An engineering change request (ECR) is created to examine the necessity and feasibility of the change, to identify parts, components and documentation that might be affected, to estimate costs and to list the resources required to implement the change.

- ECR review: The ECR is circulated for review and discussion among key stakeholders and is modified as needed.

- ECO creation: Once the ECR is approved, an engineering change order (ECO) is generated, which lists the items, assemblies and documentation being changed and includes any updated drawings, CAD files, standard operating procedures (SOPs) or manufacturing work instructions (MWIs) required to make a decision about the change.

- ECO review: The ECO is then circulated to a change review board made up of all stakeholders (including external partners when appropriate) who need to approve the change.

- ECN circulation: Once the ECO has been approved, an engineering change notification/notice (ECN) is sent to affected individuals to let them know that the ECO has been approved and the change should now be implemented.

- Change implementation: Those responsible for implementation use the information in the ECO and ECN to make the requested change

Value Engineering

The focus is on reducing costs, improving function or both, by way of teamwork-based product evaluation and analysis value, as defined, is the ratio of function to cost. We follow a systematic method to improve “value” of goods or products and services by following a customer/consumer centric approach. By enhancing value characteristics, we ensure customer satisfaction and growth of product brand\revenue

The focus is on reducing costs, improving function or both, by way of teamwork-based product evaluation and analysis value, as defined, is the ratio of function to cost. We follow a systematic method to improve “value” of goods or products and services by following a customer/consumer centric approach. By enhancing value characteristics, we ensure customer satisfaction and growth of product brand\revenue

We offer the following services to our customers as part of our value engineering offerings

- Should costing

- Cost optimization and product value enhancement

- Product Benchmarking

- Manufacturing solutions

- Product localization

- Supplier collaboration

- Market insig

VA / VE services : If you are not happy with the current level of profitability on your products OR if you are looking for an innovative way to drive cost out of your products and improve quality, we could help you with our VA/VE expertise.

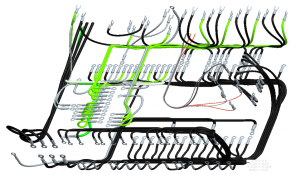

- Cable routing: Have good experience on cable routing. Have electrical component selection capability based on the design intent. can provide optimal & consistent harness design.Other Services

- Concept Generation

- P&Id creation

- Pipe routing

- Legacy Conversion

- Drawing review / update

- DFX reviews