Our Services

PRODUCT DESIGN & DEVELOPMENT

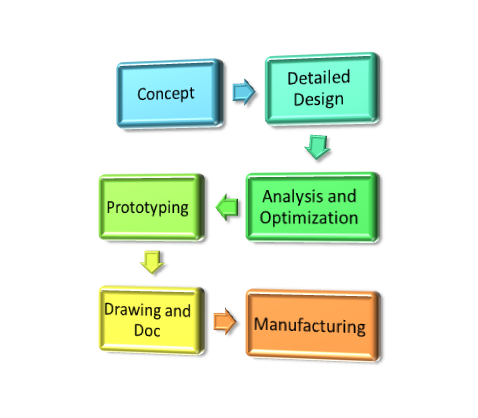

FROM CONCEPT TO DELIVERY

Our Product Design & Development services transform ideas to manufacturable & profitable products.

We guarantee useful, usable, and desirable solutions

INDUSTIRES / DOMAIN SERVED

- Consumer Electronics / Office Automation Products

- Semi-Conductor Capital Equipments

- Furniture Designs

- FMCG

- Kiosk / ATM Design

- Jig and Fixture Design

Our Engineers have a wide industry knowledge base, years of hands-on experience, and a dedication to engineering to execute fast-paced, technically challenging development efforts

This combination of our strategic consulting services and development services results in a collaborative partnership that will help launch your concepts from the drawing board to the marketplace at faster pace

JOSCOTEC’s broad experience promises that your products will be engineered to comply with all applicable industry standards and regulations by validating mechanical designs, optimizing design performance and prototyping critical components before moving on to Production tooling and Manufacturing

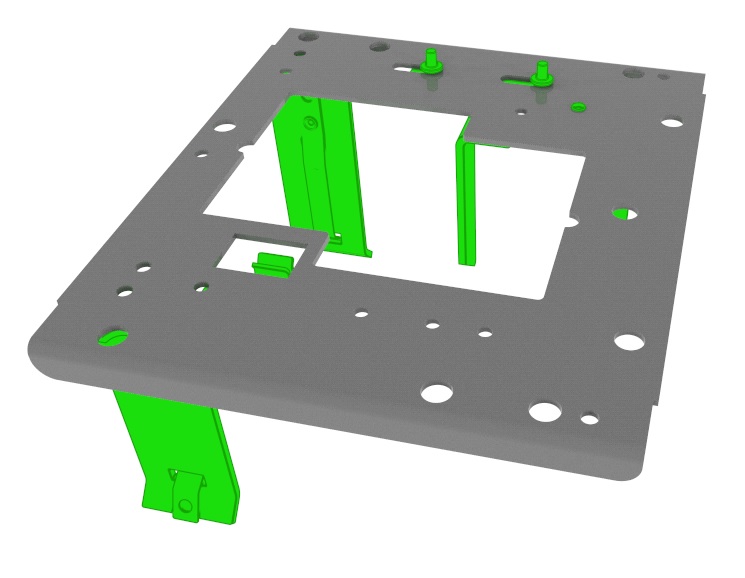

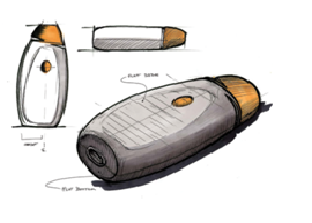

Consumer Electronics / Office Automation Products

Product packaging considering Industrial Design, Standard requirements and Manufacturability

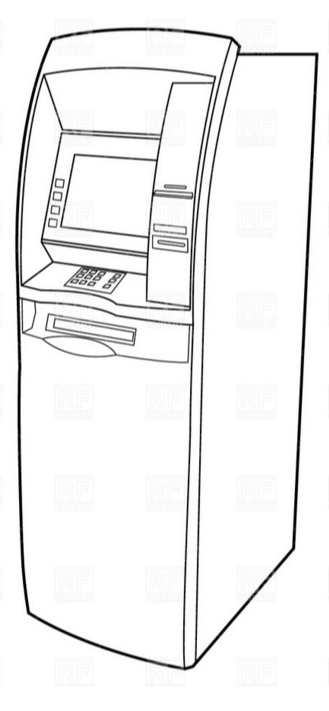

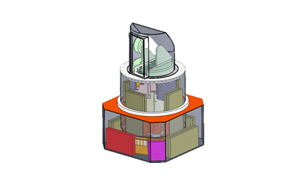

Kiosk / ATM Design

Kiosk designed to meet needs of various segment Eg. Healthcare, Sports Information or Ticketing

FMCG

This is vast segment, with multiple opportunities to innovate

Furniture

Store Layout Design, Bakery showcases are niche areas supported by our team

Semiconductor OEMs

Equipment and Enclosure Design compatible with cleanroom Requirements

Vacuum Chamber Design

Gas box \ Gas stick Design

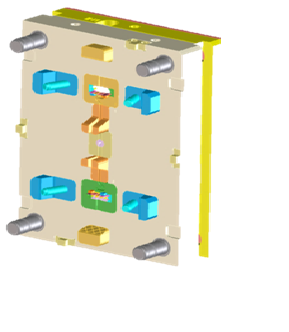

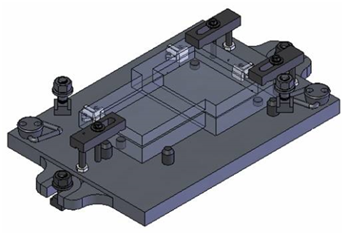

TOOL DESIGN AND MANUFACTRUING

Team comprises of Engineers graduated from NTTF with specialized degrees in Injection Mold and Press Tool Design.

Have extensive Mold design experience

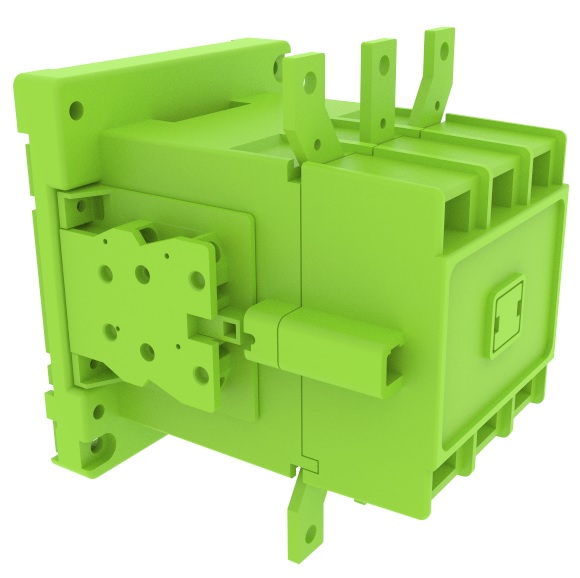

Type of Mold Designed

- 2 Plate Molds

- 3 Plate Molds

- Molds with Angular ejectors

- Mold with sliders

- Prototyping Mold

- Multiple cavity mold

- Hot runner/Hot sprue mold

Also worked with tooling vendor to resolve DFM issues if any.

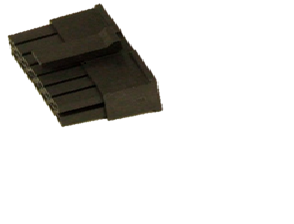

- Connector Mold Design for US connector giant

- Molds for Automotive industry, Printers, Home appliances etc.

- Component design for Molding like parts for Printers, ATM machines, Home appliances etc

DFM support for Plastic part such as

- Elimination of undercuts where possible

- Addition of drafts and rounds

- Interference check after drafts and round addition

Designed Multiple cavity molds for various type of connectors components shown above

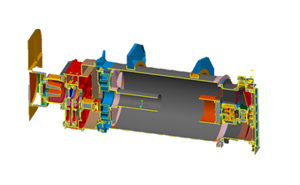

OPTO-MECHANICAL DESIGN

- Team has skills in opto-mechanical and electro-mechanical design with proven track record. Excellent skills in ultra-precision mechanical design of precision instrument, semiconductor equipment and manufacturing process equipment/fixtures.

- In-depth knowledge of precision mechanical acquisition methodology & property of materials.

- Involved in Design of Sub-systems like Beam Expanders, Beam Benders and Laser Beam Metrology equipment.

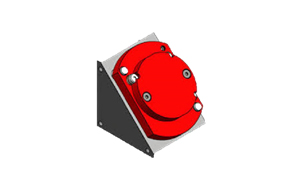

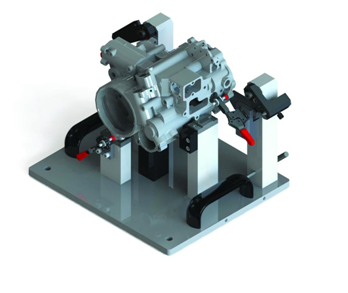

JIGS AND FIXTURE DESIGN

We have capabilities for designing Jigs & Fixtures for the following applications.

- Machining

- Industrial product manufacturing

- Automotive

- Heavy equipment

- Welding

- Fabrication

- Holding

SPECIALIZED ENGINEEIRNG SERVICES

- RSS and Worst Case analysis

Tolerance Stack up analysis

- Ensuring there is no compromise in Design intent and aesthetics

DFM review and updates for sheet metal and Plastic components

- Reverse Engineering

- Value Engineering

- ECO implementation

CAD SERVICES

- Engineering Drawing creation

- GD&T application as per ASME Y14.5

- Legacy Data conversion

- Hand Sketching – concept Generation

- Rendering with tools like Keyshot

- ECO creation to implementation

Technical Publication

- Catalog creation

- Installation Instruction document

- User Manual creation